Inside the Artist’s Studio: How Blown Glass Sculpture Is Made

October 24, 2016

The methods used to create blown glass sculpture have remained largely unchanged for thousands of years. Though aesthetic preferences may come and go, the basic techniques used to work and shape glass artwork are still the same as they were in Ancient Roman times. Take a look inside the artist’s studio at how contemporary glass art is made, from start to finish.

The methods used to create blown glass sculpture have remained largely unchanged for thousands of years. Though aesthetic preferences may come and go, the basic techniques used to work and shape glass artwork are still the same as they were in Ancient Roman times. Take a look inside the artist’s studio at how contemporary glass art is made, from start to finish.

- The Materials

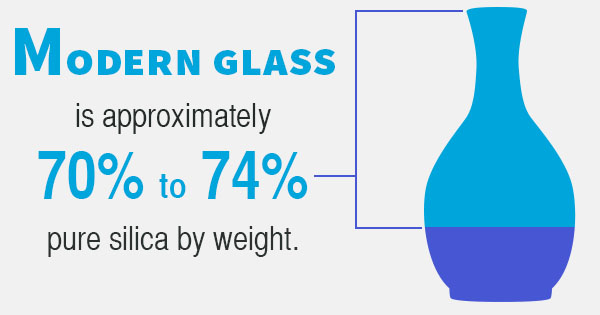

Glass is made primarily from the refined sand granules of fused quartz known as silica. Modern glass is approximately 70% to 74% pure silica by weight. The remaining materials may include soda lime or metal oxides, used to help lower the melting point of the silica, as well as colorants to infuse the clear glass with different tints and hues. - Heating and Shaping

The raw materials are first heated to a temperature of 2,000 degrees or more in a furnace. The principal glassblower, known as the gaffer, then removes the molten glass from the furnace, blowing into it from the end of a long pipe or shaping it along a cold steel surface called a marver. If the glass cools to the point where it can no longer be easily shaped, it goes back into the furnace, then blown or shaped again. This process may be repeated many times, until the desired size and shape of the blown glass sculpture is achieved. - Cooling

Glass can crack or shatter if it is moved from hot to cold temperatures too quickly. A special oven called an annealer is used to house the sculpted glass at an initial temperature of 960 degrees Fahrenheit, then cooled gradually over the next 14 hours to create a finished product. Artists may then also grind the surface to remove any sharp edges created by the movement of the piece.

The glassblowing process is fascinating both in its simplicity and versatility. No two handmade glassworks will ever be quite the same, and the potential for new forms and expressions through glass are nearly infinite. The exquisite beauty of blown glass sculpture is often enhanced by its delicacy and fragility, as well as the careful craftsmanship that must go into every single piece.